A Blog About Understanding The Toyota Production System and Gaining Its Full Benefits, brought to you by "The Toast Guy"

Accountability or Authority?

Reflecting on McGregor’s X and Y Theories of human motivation, Shigeo Shingo took the position that each of us by nature has a dual tendency: sometimes lazy and self-interested, and other times motivated and generous. Which of these behaviors dominates is directly related to the environment in which we find ourselves – call it culture.

My personal experience as a manager, and as an employee, has surely confirmed Shingo’s opinion for me. Dropped into a manufacturing management role in 1986 with NO manufacturing experience, I had the opportunity to experience a quintessential Type X culture. My predecessor, a man of considerable personal knowledge of the business, had ruled for decades with an iron fist, intolerant of opinions other than his own. I remember commenting to a friend when I first took over the manufacturing VP job, “it seems like employees are children and production employees are bad children.” Transferring from an IT role in a different building to this new world of distrust and muted dissatisfaction was indeed a culture shock for me. After a short time on the job, my general foreman presented me with a list of employees to “keep an eye on.” He thought he was being helpful. “Troublemakers,” he whispered to me.

It turns out that a few of the troublemakers became early adopters of a different kind of culture, one where employees would be seen as “the most valuable resource.” What distinguished these rabble-rousers was that they had refused to be beaten down by the previous regime. My role as a manager was, in the words of Mr. Shingo, to turn their dissatisfaction (Theory X) into “constructive dissatisfaction” (Theory Y.) At the time I described the experience as akin to freeing prisoners. I wasn’t making them participate; I was just asking for their help. That seemingly simple shift ruffled more than a few feathers in management, a humbling experience I documented in a 2012 post jokingly entitled Lead with Humiliation. Lean transformation, I discovered, while difficult for everyone, is hardest for managers.

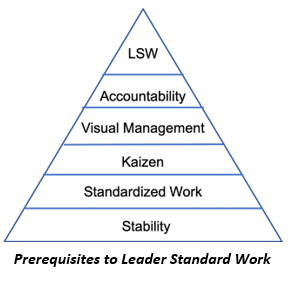

So, what does this story have to do with the words "accountability" and "authority"? In 2006, I had the pleasure of listening to David Mann, author of "Creating a Lean Culture", deliver a presentation at the Shingo Conference on Leader Standard Work (LSW.) “A novel concept,” I thought to myself. “Why not clarify the manager’s role in developing a Lean culture?” So much effort had already been put into transforming front-line systems, but very little in transforming the management systems for folks who were steering the ship. In fact, the concept to engage managers by check-listing key culture-changing management activities, caught on in a big way. Many an organization I visit today has attempted to add LSW to its Lean transformation. Unfortunately, fifteen years and millions of white boards later, what seemed like a good concept is failing in execution. Here are my observations.

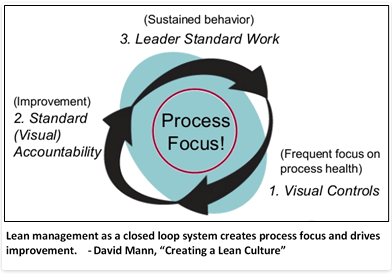

"Creating a Lean Culture" depicts the Lean management system as comprised of three parts:

- Visual Controls. Mann describes a wide variety of devices such as hour-by-hour charts intended to make each process obvious on a real-time basis. Are we on schedule? Are there defects? But very few organizations that I visit have a robust standardized work system for specifying and improving work. More common is “standard work,” which describes only the sequence of the work, often in generalities. Whether in a factory or office or operating room, the failure to understand cadence and precise composition of the work creates a very shaky foundation for accountability.

- Standard Accountability. This, for most sites I visit, is the centerpiece of the Lean management system. Operational status for a work group is summarized periodically and discussed at a brief stand-up meeting. Impediments to flow are noted and countermeasures are reviewed. The supervisor of the front line is the owner of the “Tier 1” board and is accountable meet specific KPI’s. The Tier 1 board is tied to goals and targets set at a higher-level Tier 2 board, which is owned by the manager. He or she is accountable for Tier 2. Finally, at the global level is the Tier 3 board owned by the executive. This is the principle that enables oversight and alignment of goals and measures.

Several issues frustrate the effectiveness of Standard Accountability.- First, as noted above, workers are often not given a stable, repeatable process to run. Says Mann, “until you demonstrate an improvement in stability of a process by applying the tools of Lean production, leader standard work comes across as a waste of time, a bureaucratic abstraction without real meaning.”

- Second, inadequate attention is given to actual Kaizen. Referring to the role of leader standard work, Mann notes, “the journey truly begins in earnest after the production floor has been rearranged, or procedures redefined.” But, if front-line capability to deploy countermeasures to problems has not first been established, then what system is there to manage? It’s a bit like coaching a baseball team where the players themselves have never played. We can measure the balls and strikes, but nobody has learned how to bat. Before accountability, there must be ability.

- Third, there’s that word “accountability.” Check out Roget’s Thesaurus for the synonyms: blame, fault, liability, answerability, responsibility, culpability, chargeability. Or just listen to the evening news for the connotation of the word. It’s the equivalent of referring to mistake-proofing as fool-proofing. In this sense, accountability is more like finger-pointing. Mr. Shingo condemned the word fool-proofing because it was a Theory X word. I think if he were alive today, he would also ban the use of word accountability for the same reason. When our words imply that we must make people do something, we’re perpetuating an archaic Theory X view. As managers, we should be enabling our employees to develop their capabilities. We should be authorizing them to master their crafts. Words mean something. We should choose them carefully.

- Finally, the concept of tiered accountability can provide an empowering line of sight to all employees and managers, IF it is sincerely followed by all – and when I see the occasional effective tiered accountability process it underscores the power of true alignment. More commonly, however, engagement at higher tiers is spotty; accountability in that case flows downhill. The message at Tier 1 is “S.O.S.”

- Leader Standard Work (LSW). This is the management checklist that keeps everyone practiced with the new way, a thoughtfully constructed list of periodic tasks for executives, managers and supervisors, designed to show visible commitment and support for the new way. This is the concept that first intrigued me when I listened to David Mann’s presentation in 2006: a reminder to managers to be leaders for change. My observation over the last decade is that managers who use LSW well soon become practiced and no longer need a checklist. Unfortunately, many managers create a checklist, but then don’t follow it. “My day is too unpredictable to use leader standard work,” one manager tells me. An all too common refrain. We are asking our employees to embrace change, but we are excused. It is perhaps no accident that the third edition of Mann’s book, released a decade after the original, adds a full chapter dealing with the challenge to engage management.

From the foregoing rant, it may seem that I don’t subscribe to concepts put forth in "Creating a Lean Culture"; but in fact, fifteen years after its publication, I continue to believe that if employees have both ability and authority, then the guidance and alignment provided by a Lean management system is imperative. That is Theory Y. As David Mann reminds us, “Execution is the key to lean management.” The authority to execute, today as in 2006, rests squarely on the shoulders of executives.

What is your experience creating a Lean management system? Can you share a story or observation?

O.L.D.

Hope to see you all at our 15th annual Northeast LEAN Conference in Hartford, October 23-24. The topic of engagement – employees and execs – will be a main focus. Our theme this year, Total Employee Involvement, combines the knowledge and experience of leading practitioners and experts. Want more information? Click here.