A Blog About Understanding The Toyota Production System and Gaining Its Full Benefits, brought to you by "The Toast Guy"

Uncommon Sense

“Never let a good crisis go to waste.” This advice, attributed to Nicolo Machiavelli, and later cited by Winston Churchill at the conclusion of WWII, resonates once again in the aftermath of the COVID-19 pandemic. Widespread shortages of products, services, raw materials, fuel, equipment, transportation and people have shocked the system in our land of plenty, creating an almost universal burning platform. From manufacturing to healthcare to service and even the public sector, providers can’t deliver – this while costs are rising, unemployment is at record lows and customer demand is through the roof. Could it be that this tsunami of challenges is driving providers to experiment with ideas that just a few short months ago were light years from top of mind?

One factory manager noted recently for example, “It’s just a no-brainer that when you can’t find workers, you can increase productivity by removing waste from the job.” Funny that this should be considered a no-brainer now, when the supply of employees is limited. But I’ll take it. The pandemic, it seems, has elevated the role of the frontline while casting a brighter light on the shortcomings of off-shoring. In 2011, when the theme of GBMP’s Northeast Lean Conference was “Made Lean in America,” several supply chain pundits shared with me in no uncertain terms that this was wishful thinking. It would never happen, they said. Times change.

For organizations that have traditionally responded to growth by acquiring more equipment, telescoping purchase times for equipment have turned our attention also to making the best use of the machines we already have. Practices like preventative maintenance and quick changeover address the scarcity of equipment and equipment operators.

And, then there are the omnipresent material shortages. At the start of the pandemic, many providers took the commonsense step to actually reduce supply, even as consumers horded whatever was available. The resulting deficits have now placed keen attention on what’s made and when. “Certain alloys are super scarce right now,” a manager of a machine shop related to me, “so we can ill-afford to produce any material that we cannot ship.”

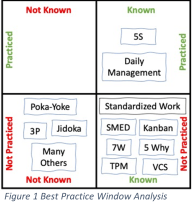

Referring to the window analysis in figure 1, in times of plenty, Lean improvement efforts fell more into the “known-but-not-practiced” category. Let’s call it the mediocrity zone. As a VP of Operations confessed recently, “Yes, we attended the Lean 101 workshops in the past, and dabbled with some experiments; but in reality, these methods are not a part of what we do.” I hear the same message in every industry. The props may change, but the half-hearted practice is the same.

My teacher, Hajime Oba, used the word “commitment” to describe the difference between Lean dabblers and organizations that seize the opportunity to gain significant benefit from TPS. With cautious optimism, I believe that commitment potential may never be greater than today. I have observed in the last six months the greatest resurgence of my career in interest to learn and practice problem solving and continuous improvement methods. This crosses every industry, but shares a similar burning platform, one that no one would have predicted before 2020. Writing in 1988 about the Toyota Production System, Taiichi Ohno stated “The oil crisis opened our eyes . . . “ Or as Shigeo Shingo noted around the same time, “the biggest obstacle to improvement is the will to improve.” Here we are more than three decades later. Let’s not let a good crisis go to waste.

O.L.D.

P.S. Speaking of… GBMP’s 18th Annual Northeast Lean Conference is coming up in less than two months. Have you checked out the agenda yet? We are so excited about our theme – “Amplifying Lean: The Collaboration Effect” and sincerely hope you will join us for the 2-day event which will feature four terrific keynote presentations plus more than 30 breakout sessions, a dozen benchmarking organizations in The Community of Lean Lounge and the chance to network with hundreds of Lean practitioners just like you! Read all about it.

By the way – if you can’t make it to Massachusetts, don’t worry. All of the sessions will be streamed – LIVE – so you and your team members can attend from anywhere in the world! Register Today.