What is blocking your CI success?

Obstacles Are Inevitable. Complacency Isn’t.

For more information about engaging GBMP for customized onsite Lean & Six Sigma training for your organization or to schedule a free Lean operational assessment please contact Jamie Millman at 617-710-7033 or by email at Jmillman@gbmp.org

For inquiries about our public Lean training workshops or annual conference, please call Lela at 617-969-1396 ext. 2

For questions about our Lean training games, videos, books, Leanflix, or our self-paced learning modules, call Tracy at 617-527-0268

The sobering truth is most of the time spent on any process is waste. Some estimates are upwards of 95%. We all spend many precious resources like money, time, and effort on a process, but only a small slice of that actually delivers value to the customer.

Without a shared understanding of what waste is, how can you expect your team to see and eliminate it. As Shigeo Shingo said, “the most dangerous kind of waste is waste we do not recognize.”

Seven Wastes has become a common term in the Lean world. Memorizing acronyms like TIMWOOD is a start. (We have a favorite acronym at GBMP: STOP WMD = Stop Wasting my Day. ) J But memorization is not at all the same as recognizing the individual wastes and the impacts they have on quality, productivity and employee morale. Shingo’s work on the Toyota Production System identified and broke down the seven wastes and explained them in a practical, actionable way. He taught that waste elimination requires both the right tools (means) and the motivation to use them. It is not enough to memorize the 7 wastes; you must care about eliminating them. Recognizing waste is the first step. But to truly improve, you also need the desire to act. Shingo called this “constructive dissatisfaction”, not just recognizing problems, but wanting to fix them.

Shingo built his concepts based on some of the work of Frank and Lillian Gilbreth, early pioneers in studying work motion and efficiency. Their research, dating back to the early 1900s, helped shape the way we all think about the difference between value-adding work and waste. A good way to recognize which you are doing at a particular moment in time is to ask yourself, “is this task adding value for my customer?” If the answer is no, it is waste.

Whether you are moving parts, information or people, the seven wastes are the same. It doesn’t matter if you work in a factory or an office. People often say, “you can’t see knowledge work, it’s invisible” but, in fact, wastes apply just as much to administrative and office processes as they do in manufacturing. Here are some examples of a few of the wastes. Anything sound a little too familiar?

Storage. Inventory is often seen as a safety net, but it can hide big issues beneath the surface. Lower the water (reduce inventory) and suddenly the rocks (your real problems) are exposed. Shingo highlighted two types of delays which cause inventories to grow: Lot delay (waiting for a whole batch to finish before moving it on) and process delay (material waiting because the machine or person isn’t available). Both types of delay add no value, but extend the elapsed time to deliver.

Transportation. Traditional functional layouts require that material and information be passed along from one department to the next on its way to completion. In my factory, I discovered that products no bigger than my fist traveled miles within our small factory with transit time greater than 40% of production time. With a few layout changes we cut that time in half pretty quickly.

Overproduction, making more than is needed or making it too soon, creates inventory that’s not needed immediately. This is the worst waste, because it creates other wastes like storage (inventory) and transportation. The ideal is to deliver the exact customer requirement immediately. To reduce this waste, set a target to produce less – closer to what your customer actually needs. Keep asking yourself and your team, “Why not make half as much?” Don’t stop asking that question.

Processing waste is hidden in things that look like work, for example inspection or sorting. It also occurs when the quality standard is unclear and varies according to personal opinions of persons doing the job, which is referred to as over-processing.

Waiting is time wasted when people or equipment must wait for information or material. Waiting has many causes like an upstream supply problem or a machine down, or missing person, or discovery of a defect. Identify those, and the waiting melts away. A couple of tips:

Motion is any movement like reaching, searching or walking. All motion is waste. Look for small motions to reduce (like reaching a tool) as much as for large motions (like walking to the stockroom.). The smaller motions occur frequently and add up to a surprising opportunity for productivity improvement. One final tip: When motion waste is reduced, make sure the time is filled with productive work – or perhaps an occasional planned rest break. People hate waiting, it adds zero value and kills productivity.

Defects is typically the waste that gets the most attention. It creates delays, rework, scrap, and the need for additional inventory. Remember, even if a part can be reworked, you’ve already scrapped out the time of the person and machine that built it.

Finally, all of the seven wastes interact with and compound one another. Long transport routes encourage larger production lots to reduce the number of trips between departments. But, delivering huge lots of materials creates clutter and makes work harder. Small, frequent, just-in-time deliveries, arriving precisely when they’re needed cuts down both storage and transportation waste. Real improvement takes several changes and improvements working together.

The seven wastes aren’t just a checklist to memorize. They’re a framework for recognizing problems and motivating action to eliminate them. A quote from Shigeo Shingo summarizes the connection between recognizing waste and taking action:

The seven wastes aren’t just a checklist to memorize. They’re a framework for recognizing problems and motivating action to eliminate them. A quote from Shigeo Shingo summarizes the connection between recognizing waste and taking action:

When I visited company K, I noticed the slogan “Eliminate Waste” posted on the wall of the president’s office. So, I remarked to the president, “You must have many stupid employees here at your company.”

“That’s not true,” he replied. “Why do you say that?”

“But the poster there says ‘Eliminate Waste.’”

“What’s wrong with that? Isn’t eliminating waste a good thing to do?”

“True. But don’t you have that slogan posted, because here at your company people don’t automatically try to eliminate recognizable waste? Anybody who recognizes waste will try to eliminate it. The real problem is when people do not recognize waste when they see it.” (Non-stock Production, p. 69)

Bottom line: Once your team members recognize how much of a drag the 7 wastes have on their work, they’ll be motivated to eliminate them: STOP Wasting My Day!

Obstacles Are Inevitable. Complacency Isn’t.

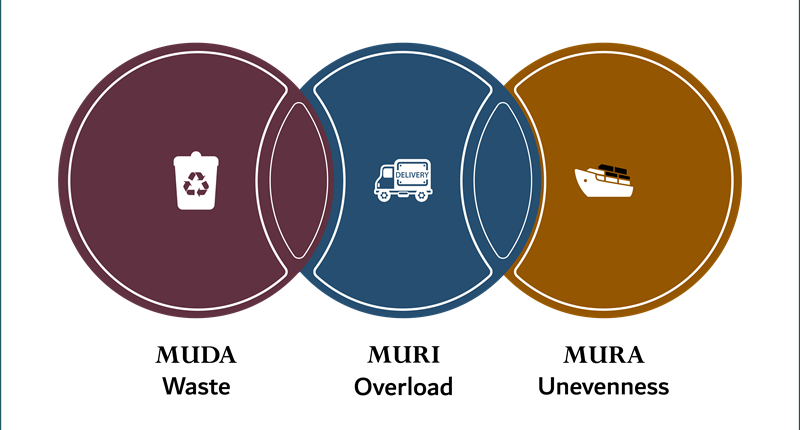

Why Unevenness (Mura) Sinks Even the Best Canoers

If you’ve been asked to lead continuous improvement, this scenario may sound familiar: teams are learning Lean methods, projects are underway, and...